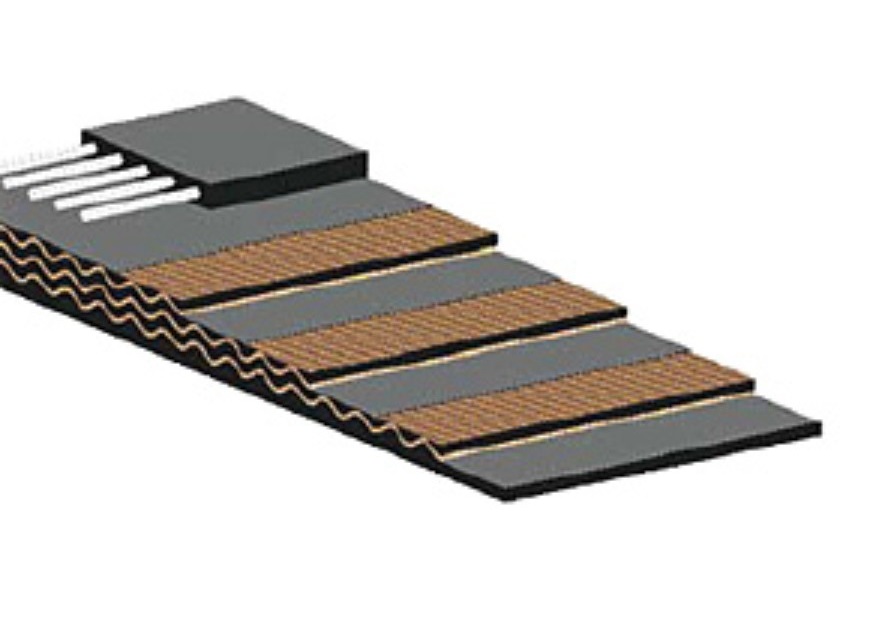

Multi Ply conveyor belts for excelent tear resistance

Conveying bulk solids can sometimes cause difficulties, sharp-edged, large pieces of undefined shapes, unfavourable feeding conditions, material pile-ups could result in longitudinal cuts or punctures in the belt.

Our company provide a technical and cost-efficient solution, which is the Ripcheck conveyor belt with an additional impact-resistant breaker installed above the carcass.

FEATURES & BENEFITS

PRODUCT SPECIFICATIONS

Other constructions and widths on request. Ripcheck conveyor belts also available in Chevron version.

GALLERY

LITTERATURE DOWNLOADS

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.